How It's Crafted

KAGAMI uses a technique called “copper-wheel engraving,” which is regarded as the finest technique in engraving (Gravure).

A basic design drawn on the surface of glass is engraved diligently with a copper-wheel to which fine abrasive emery sand powder dissolved in oil is applied.

Mold-blowing / Free-blowing

Mold-blowing / Free-blowing

In mold-blowing, a glob of molten glass is spooled at the end of a blowpipe and air is blown into the glob. Then, it is placed into a mold and further air is blown into the mold to form the glass into a desired shape.

Free-blowing is a fundamental technique for shaping glass. It does not use molds at all but instead blows glass into various shapes in mid-air. The fundamental technique of free-blowing is utilized in the process prior to placing glass into a mold for mold-blowing, or for producing handles of beer mugs.

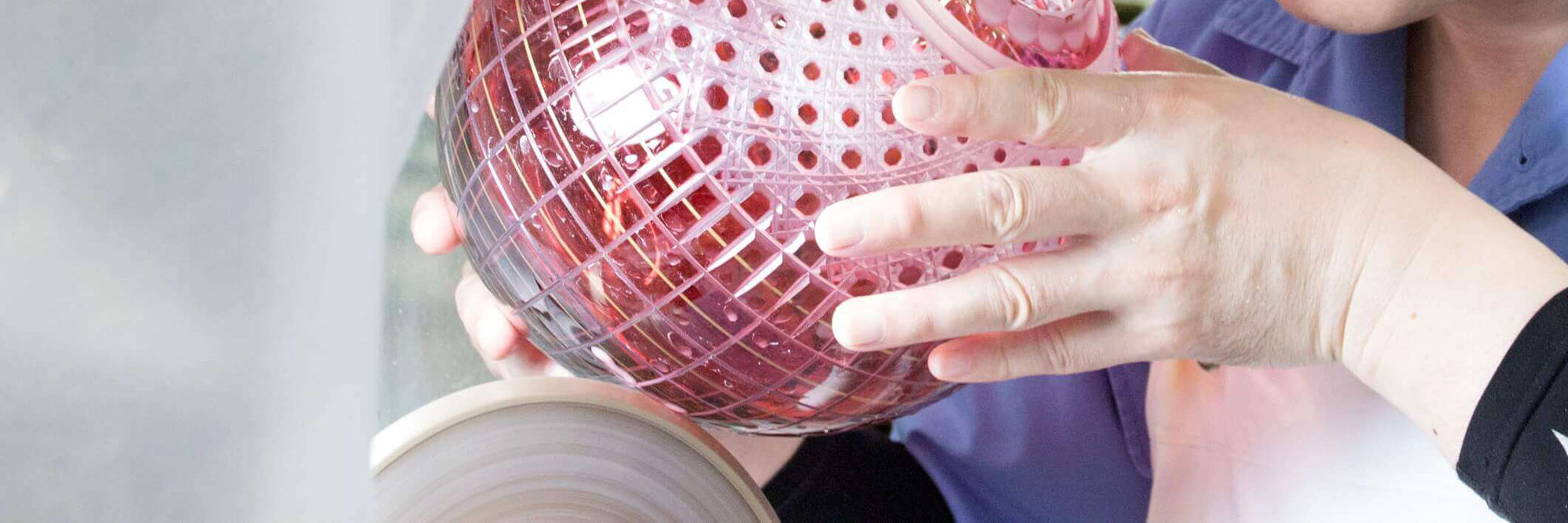

Cutting

Using this technique, geometric patterns are rendered on the surface of glassware with various grinding wheels. Basically, all cut patterns are combinations of the following four types of cuts: V-shaped, convex, hollow, and flat. Cutting is the most important processing technique that makes the brilliance of crystal glass stands out remarkably.

KAGAMI's cut glass, featuring a high refractive index, has earned unparalleled reputation both in Japan and abroad for the depth and the sharpness of cuts as well as for its elegant design.

Engraving (Gravure)

KAGAMI uses a technique called “copper-wheel engraving,” which is regarded as the finest technique in engraving (Gravure).

>A basic design drawn on the surface of glass is engraved diligently with a copper-wheel to which fine abrasive emery sand powder dissolved in oil is applied.

Through further polishing and Bokashi (blurring with gradation) processes, subtle, shading effects are rendered, which are unachievable by normal cutting techniques.

This technique was developed in the Bohemia region in central Europe with the advent of Bohemian Crystal, and is an extremely difficult technique to master. This technique was introduced to Japan by Kozo Kagami and has been passed down to the present day.

Video

-

Molding (Flower Vase)

This is the process where molten glass at a temperature of over 1000℃ is wound around the tip of a blowpipe and then colored using a mold-blowing process to create a vase.

-

Molding (wine glasses)

This is the process of drawing the stem of a wine glass from the glass that has been blown into a mold on the end of a blowpipe.

-

Cutting(Kiriko)

This technique involves carving geometric patterns into the surface of glass by grinding it with various grinders.

-

Engraving (Gravure)

This technique involves applying fine diamond sand dissolved in oil to a copper disk attached to a rotating shaft, and then painstakingly carving a drawing into the surface of glass or other material.

Craftsman introduction

Technical ability to cut exactly as you imagine

Tomokazu

Noguchi

Ibaraki Prefecture

Traditional Craftsman

Kiriko Workplace: Foreman

A Kiriko craftsman who creates Kagami Crystal products that utilize the high refractive index. He is the successor to the most important processing technique that accentuates the beauty of crystal glass.

Kiriko (cutting) is a technique in which the surface of glass is carved with various grinders to carve geometric patterns. It is one of the most important processing techniques that highlight the beauty of crystal glass.

Since joining the company, Noguchi has been dedicated to Kiriko and has processed many of KAGAMI's products. In 2020, his high level of technical skill was recognized and he was certified as a traditional craftsman of Ibaraki Prefecture.

The molding process is the foundation of all our products.

There are no shortcuts to mastering it, and we are still in the process of improving.

Morihiko

Takei

Ibaraki Prefecture

Traditional Craftsman

Molding Craftsman

A craftsman blows life into molten glass to create a shape. He shapes the glass without applying excessive force, and his work is both powerful and delicate.

Glass shaping craftsmen blow air into molten glass to shape it.

The shaping process that forms the basis of the product begins with winding the glass onto a blowing rod, and all adjustments to thickness and weight are made by the craftsman's experience and intuition.

By blowing the glass into a mold, a certain degree of shape is kept consistent, but for example, the length of the stem of a wine glass is created by hand by the craftsman.

Also, the shaping method differs depending on the shape and size, and blowing different glasses is not easy.

Takei makes use of his many years of experience in shaping numerous products to shape all kinds of products.